Unlocking Potential with Baldwin

Podcast de Baldwin Technology

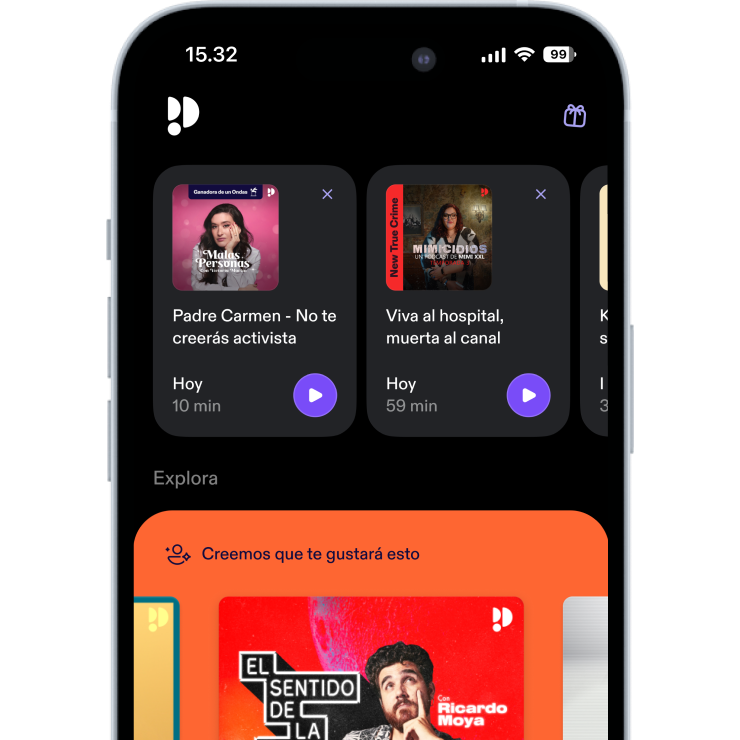

Disfruta 30 días gratis

4,99 € / mes después de la prueba.Cancela cuando quieras.

Más de 1 millón de oyentes

Podimo te va a encantar, y no sólo a ti

Valorado con 4,7 en la App Store

Acerca de Unlocking Potential with Baldwin

We're fueled by 100 years of innovation, providing the top hardware, software, and consumables to automate, enhance, and apply intelligence to production processes. Join us and learn how you can unlock your full potential.

Todos los episodios

18 episodiosIn today's dynamic business landscape, adaptability is key to survival. The printing industry, known for its resilience and evolution, recently faced an unprecedented and formidable challenge with a worldwide paper shortage. This part 1 episode of Unlocking Potential dives deep into the heart of this crisis, exploring its causes, consequences, and actionable solutions. At the core of this predicament lies a complex web of factors. Paper mill closures, supply chain disruptions, and shifting demand patterns have converged to create a perfect storm. The consequences ripple through the industry, affecting printers, publishers and paper mills alike. To understand the depth of how the crisis unfolded, it's essential to unpack these interconnected issues. In our conversation with industry experts -- Toni McQuilken, Kent Tucker and Julie Brannen -- we examine the root causes of the paper shortage. Toni McQuilken, Senior Editor at PRINTING United, offers insights into the industry's struggles and adaptation to these challenges. Kent Tucker, Vice President of Tucker-Castleberry, shares real-world experiences from a family-owned printing company navigating uncharted waters. Julie Brannen, Director of Regional Sales at Monadnock Paper Mills, lends her extensive knowledge of the industry to the discussion. Our guests bring clarity to the multifaceted challenges posed by the recent paper shortage crisis. They emphasize the need for flexibility in paper choices and pricing adjustments. These insights shed light on the adaptive strategies that businesses are adopting to survive and thrive in turbulent times. From diversifying supply chains to exploring new product lines, the printing industry is evolving to meet the demands of today's market. Join us as we navigate the chaos in the printing industry, seeking answers to critical questions and unveiling strategies for resilience. In a world where change is constant, adaptation becomes the key to unlocking success. Don't miss this episode of Unlocking Potential – your guide to staying ahead in the ever-evolving printing industry.

The 3D printing revolution is no longer a futuristic concept; it’s a present-day reality. Over the past decade, the additive manufacturing industry has undergone a seismic transformation, with a projected global market value of $34.8 billion by 2024. From intricate medical devices to jet engine prototypes, the adoption curve of 3D printing has soared, disrupting traditional industries. Meanwhile, hobbyists are tapping into this technology to craft personalized items ranging from jewelry to home decor. How is the 3D printing revolution transforming both the industrial landscape and the world of personal creativity? In the latest episode of Unlocking Potential [https://marketscale.com/shows/baldwin-technology/], host Gabrielle Bejarano [https://www.gabriellebejarano.com/] welcomes three experts to dive into the dynamic world of 3D printing. Wyatt Levy, Head of Product Development at Henkel, Beverly Tan, Founder of Ecovate 3D, and Kevin Joesel, Sales Executive at AMS Spectral UV, a Baldwin Technology Company, offer a panoramic view of the 3D printing spectrum, from its transformative impact on industries to empowering individual hobbyists. Bejarano, Levy, Tan, and Joesel’s discussion includes: * The evolution of 3D printing and its transformative impact on industries and hobbyists * The latest material innovations and prospects * The blending of precision and creativity in 3D printing Wyatt Levy, the Head of Product Development at Henkel, brings expertise in photopolymer systems for DLP and Stereolithography-based 3D printing. Beverly Tan, the visionary behind Ecovate3D, offers a unique retail perspective with her space dedicated to 3D printers, filaments, and maintenance services. Rounding out the panel is Kevin Joesel, a sales maestro from Baldwin Technologies, whose 25-year industry tenure provides a deep understanding of the 3D printing landscape. Learn more about 3D printing by connecting with our guests: Wyatt Levy [https://www.linkedin.com/in/wyattlevy] Beverly Tan [https://www.linkedin.com/in/beverlytan] Kevin Joesel [https://www.linkedin.com/in/kevin-joesel-uvcuring/]

The digital landscape is swiftly changing, and so too is the need for efficient and reliable print inspection software. With the rise of automation, there's a growing demand for tools that not only simplify the workflow but also provide accurate and comprehensive print inspections. Enter PQV 4.0, the most sophisticated print inspection software currently available. In an era where every pixel counts, the stakes are high, and the right software can mean the difference between flawless execution and costly errors. So, what is the main question surrounding the introduction of PQV 4.0? "How can this new software improve my workflow and overall print inspection process?" In this episode of Unlocking Potential by Baldwin, host Gabrielle Bejarano and guest John Cusack, Business Development Manager, delve deep into the capabilities of PQV 4.0, a ground-breaking print inspection software that guarantees precision, reliability, and user-friendly interfaces. Main points of the conversation include: * Introduction of Wizard IQ, a new concept aimed to bring simplicity to print inspection technology, making it accessible to all operators, regardless of skill level. * The power of automation in PQV 4.0, offering faster setup times, better repeatability and more reliable outputs. John Cusack, with his extensive background in business development and specialization in defect detection platforms, brings valuable insights into the conversation. His main responsibility at Baldwin Technology is around defect detection platforms, focusing mainly on the printing industry and quality aspects.

The younger generation can be exposed to the job satisfaction and diversity of the printing industry through social media videos.

Printing has always been in demand and is as relevant as ever. According to Mordor Intelligence, the global commercial printing market was valued at USD 433.79 billion in 2021. It is projected to be worth USD 484.22 billion by 2027, registering a CAGR of 1.74% during the forecast period (2022-2027). However, the printing industry is not experiencing an influx of young talent. What strategies can be adopted to ensure younger job seekers recognize the beauty of working in the industry? On today’s episode of Baldwin’s “Unlocking Potential” Podcast, host Gabrielle Bejarano sits down with Adriane Harrison, Vice-President at Printing United Alliance, Mike Nelson, Engineering Manager at Baldwin Technology’s AMS Spectral UV business and Rich Bennett, President of Baldwin Technology’s AMS Spectral UV business, to discuss how to attract young talent to the industry. The trio discussed: 1. What makes printing glamorous and how to present it to the younger talent 2. The job satisfaction associated with the printing industry 3. How to approach Gen Z on the evolution and benefits of working in the printing industry “Printing is fun, cool and high-tech, and contrary to popular misconceptions, a printing shop is most bright, clean and beautiful. Another perk of working in the printing industry is seeing things transform all day, which is really satisfying. This improves job satisfaction as you can immediately see the outcome of your efforts. One strategy to attract the younger talents is uploading videos that show the cool processes involved on different social media platforms,” explained Harrison. “The print industry is not excluded from the evolutionary and revolutionary process. Previously, about four to six people are required to run the press machine. However, now you only need one person for the job. The entire process has become more digitalized,” noted Bennett. “First, the creativity of the industry is something that always amazes it. We work on various systems that use various processes in the engineering discipline. One could enjoy various paths coming into the print industry because it allows for diversification,” stated Nelson.

Valorado con 4,7 en la App Store

Disfruta 30 días gratis

4,99 € / mes después de la prueba.Cancela cuando quieras.

Podcasts exclusivos

Sin anuncios

Podcast gratuitos

Audiolibros

20 horas / mes